FLAME RESISTANT FABRIC CONVEYOR BELT FOR COAL MINE

Executive standard: MT/T 914-2019

Widely used in coal, mining, ports, metallurgy, electric power, chemical industry, casting, cement and other industries and places that require fast and efficient transportation of materials.

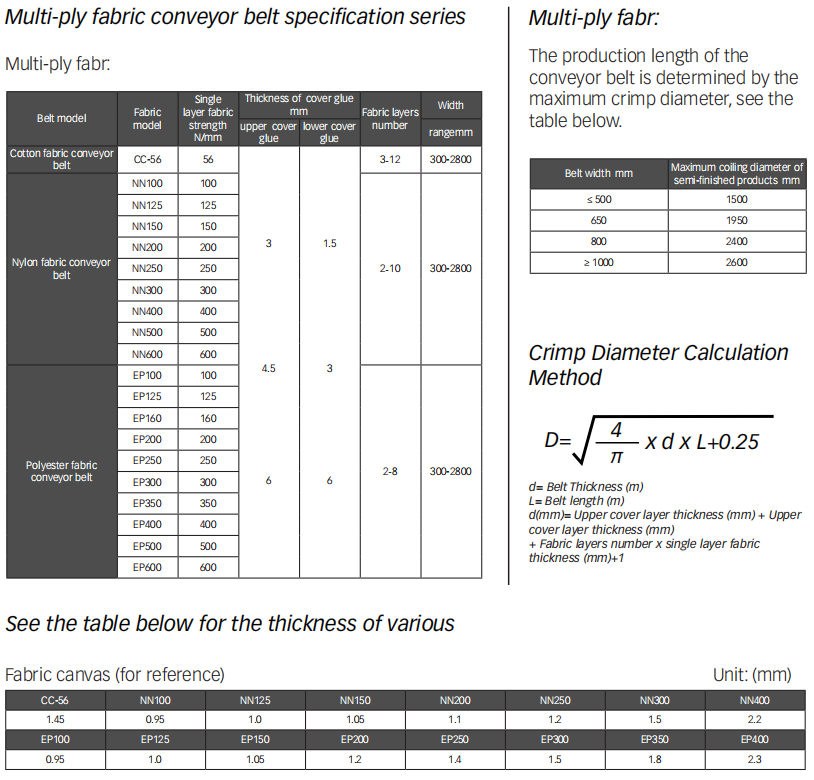

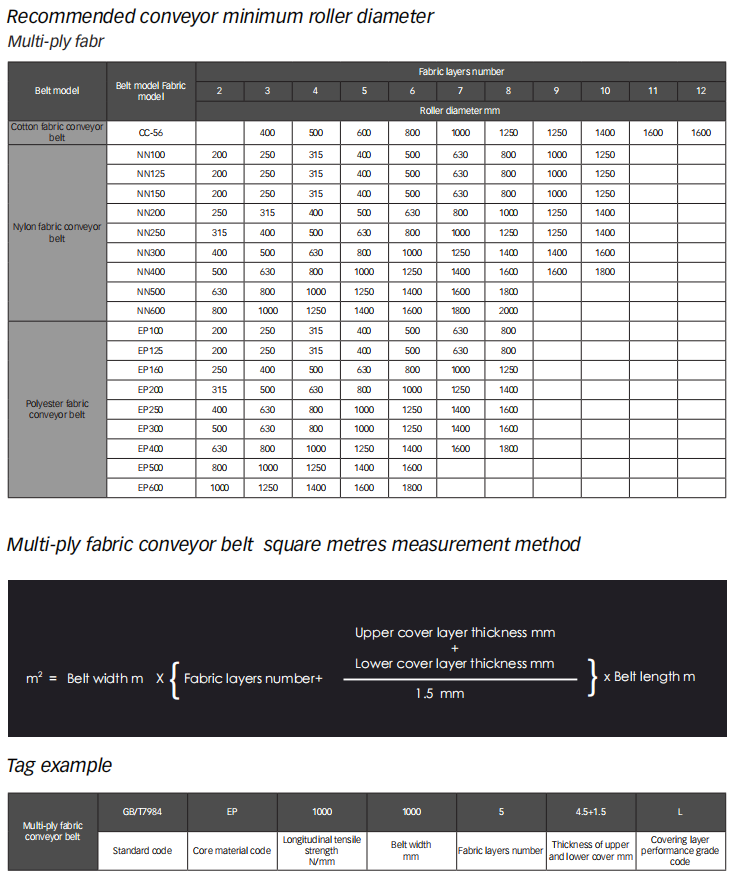

MULTI-PLY FABRIC CONVEYOR BELTS

1.COTTON CANVAS 2.NYLON CANVAS 3.EP CANVAS

Nylon canvas conveyor belt: light belt body, good elasticity, high strength, impact resistance, good groove forming performance, suitable for medium and long distance, large volume and high speed conditions to transport materials. There are nylon 6 canvas core and nylon 66 canvas core. The strength of the two is roughly equal, but the thermal size stability of nylon 66 is better.

EP canvas conveyor belt: high initial modulus, good thermal stability of the belt body size, impact resistance, suitable for medium and long distance, large volume and high speed conditions to transport materials.

Cotton canvas conveyor belt: It is a traditional conveyor belt, suitable for conveying materials in short and medium distances.

Executive standard: In addition to the national standard GB/T7984, the layered fabric core conveyor belt products can also execute ISO 14890, German DIN 22102 standard, Japanese JISK 6322 standard, and Australian AS 1332 standard. The general-purpose flame-retardant conveyor belt executes the GB/T 10822 standard, the heat-resistant conveyor belt executes the GB/T 20021 standard, the cold-resistant conveyor belt executes the HG/T 3647 standard, the oil-resistant conveyor belt executes the HG/T 3714 standard, and the acid and alkali-resistant conveyor belt executes the HG/T 3782 standard. If customers have other requirements, the supply and demand sides can negotiate and determine.